|

上海智尊工业自动化有限公司 |

| |

|

|

|

| 您最信赖的进口备件供应商 |

EBM PAPST

|

依必安派特公司于1963年在德国成立。作为在电机和风机产业领域的技术领导者之一, 依必安派特拥有55家分支机构在世界各地为客户提供专业地风机及电动机的解决方案与服务。 |

||||||||||

Email询价更迅捷: info@zzindustry.net |

||||||||||

|

||||||||||

|

||||||||||

Compact, quiet and efficient The overall efficiency and acoustic behaviour of the fans has been significantly improved for the new plug fans. The new blade geometry with a diagonal trailing edge has positive effects on theaerodynamic behaviour and on the running smoothness of the fans. |

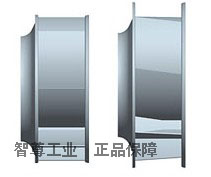

The impeller was optimised again for the new series; compare before (left) and after (right) |

|||||||||

The same is true for the implemented nozzle contour. Previously, a standard pressure tap was integrated here to regulate differential pressure via a threaded nipple. A ring line is also possible on request. |

||||||||||

|

||||||||||

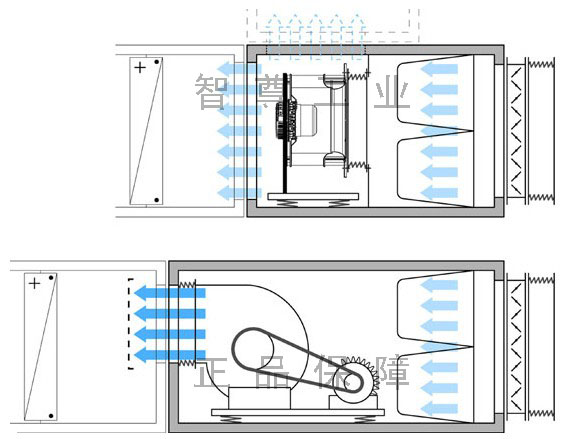

Plug fans are very compact because the EC motor is integrated directly in the impeller. A belt drive between the motor and the fan, which is commonly used otherwise, is not necessary. This reduces not only the required installation volume – always desirable for ventilation and air-conditioning technology – but also the associated installation effort. The power electronics integrated in the EC motors are compatible with all common supply voltages; depending on the motor type, either from 200 V to 277 V for single-phase AC or 380 V to 480 V for three-phase current supply. The frequencies lie at 50 or 60 Hz, respectively. The air performance and efficiency are unaffected by frequency changes. This means that the same fan type can be operated on different power systems without further ado. The fans are designed for a service life of more than 40,000 operating hours. That corresponds to a continuous operation of more than 4.5 years, operating under full load and at the maximum permitted ambient temperature. When operating under partial load or at lower ambient temperatures, the value is significantly higher. The "spider mount" allows a variable installation position of the fans – installation is possible with either a horizontal or a vertical motor shaft position. The large sizes are intended for horizontal installation, where vibration elements can be attached to the base frame to provide isolation from the environment. Additional optional measures can also be realised to enhance resistance to corrosion. This means that the fans can also be used in hygiene equipment. With this EC plug fan series, highly efficient, easily regulated and high-performance fans for ventilation and air-conditioning technology are easily accessible. The fans significantly exceed the requirements of energy efficiency class A+ stated in German manufacturer's association RLT Directive 01, "General Requirements for Ventilation and Air-conditioning Devices" |

||||||||||

Ebm-Papst Mulfingen GmbH & Co. KG

| 联系我们 | 常见问题 | Copyright@2009 上海智尊工业自动化有限公司 | ||